When Apple took the stage to unveil the iPhone 17 line, the headline change wasn’t a new camera or fresh color. It was the frame. After only two generations of titanium Pro models, Apple quietly walked away from that premium metal and moved the entire iPhone 17 family – apart from the Air – to aluminum.

Officially, the company talked about better heat dissipation and more stable performance. Unofficially, a lot of us wondered: is this really about thermals, or is aluminum just cheaper and easier to work with?

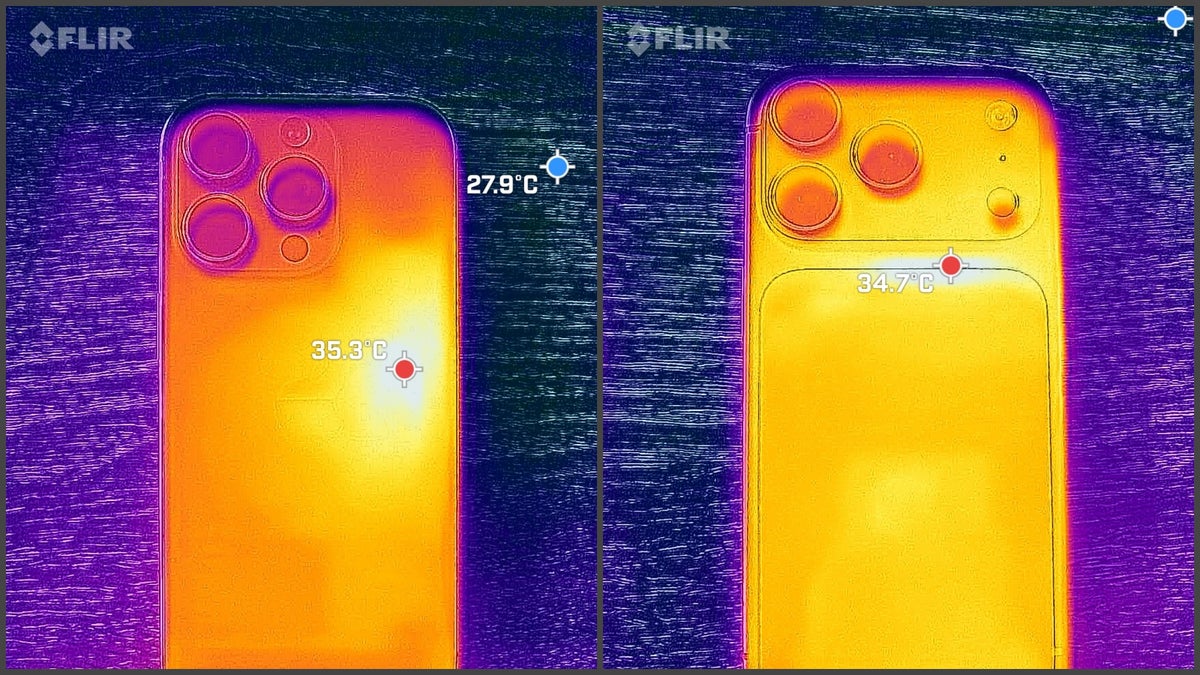

To move beyond marketing slides, we did what any slightly obsessed phone nerd would do: we reached for a thermal camera. With a FLIR One clipped on, we put the iPhone 16 Pro, with its titanium frame, head to head against the new aluminum iPhone 17 Pro. Same room, same workload, same starting conditions. The goal was simple – see how the phones heat up under stress, where that heat goes, and how quickly they recover once you let them rest.

Before diving into the thermal photos, it’s worth rewinding a bit. Apple’s Pro materials have been on a journey. The iPhone X, 11 Pro, 12 Pro, 13 Pro, and 14 Pro relied on stainless steel: heavy, fingerprint-prone, but unmistakably premium in the hand. Then came the iPhone 15 Pro and 16 Pro, which switched to titanium. That delivered lighter phones and a different, more matte texture, but it also came with a subtle downside – titanium isn’t particularly good at moving heat around. Compared to aluminum, it has noticeably lower thermal conductivity, which means hot spots tend to stay concentrated instead of spreading across the frame.

The timing of that titanium era overlapped with one more key change: Apple’s first 3 nm chip. With the A17 Pro, we learned a familiar lesson in mobile silicon. You can build a very fast CPU and GPU, but if you can’t keep it cool, that power is only available in short bursts. Owners of A17 devices quickly discovered that heavy games, long 4K video recordings, and big exports in video editors would push the chip into thermal throttling. Framerates dipped, export times slowed, and some people even reported the phone feeling uncomfortably hot around the buttons while the rest of the frame stayed relatively cool.

For the iPhone 17 Pro, Apple didn’t just change the frame material. It also added something that Android manufacturers have quietly been using for years: a vapor cooling chamber. Companies like Asus, Samsung and others have long relied on these chambers in gaming phones and flagships to help keep SoCs under control. Essentially, the vapor chamber sits between the chip and the chassis and acts as a flat, spread-out heat highway, instead of a single thermal pipe or a small graphite pad.

In simplified terms, a vapor chamber is a sealed, thin metal enclosure that contains a tiny amount of working fluid. Under the processor, the fluid absorbs heat and turns into vapor. That vapor then travels to cooler sections of the chamber, where it gives up its heat to the metal walls, condenses back into liquid, and wicks back toward the hot spot via a micro-structured internal surface. It’s a continuous loop that spreads heat across a much larger area, letting the entire phone body help out instead of letting one tiny patch do all the work.

Now, this is where aluminum comes in. Even the best vapor chamber is only as effective as the shell it’s connected to. Aluminum happens to be a fantastic thermal spreader compared to titanium and even stainless steel. That means any heat the vapor chamber passes to the frame can move more freely through the body, rather than pooling in one angry hot corner. On paper, the combination of vapor chamber plus aluminum frame should lead to more even temperatures and better sustained performance – even if the phone sometimes feels warmer to the touch overall.

Benchmarks back this up. In 3DMark’s Wildlife Extreme Stress Test, the iPhone 17 Pro doesn’t just start higher than the iPhone 16 Pro; it also holds its performance for longer and bottoms out at a higher minimum score. That’s a classic sign of improved cooling: the chip doesn’t need to slam the brakes as aggressively to protect itself, so the performance curve is flatter and more stable. But benchmarks are abstract. To understand what’s physically going on, we went back to the FLIR camera.

We began with an idle baseline. Both phones sat untouched for about 20 minutes on the same desk, in the same room, without any apps running in the foreground. The FLIR image at this stage showed what you’d expect: both the titanium iPhone 16 Pro and the aluminum iPhone 17 Pro were fairly uniform, with only minor variations around internal components. Their hottest spots were only a few degrees above ambient. In other words, at rest, neither material has a dramatic advantage. Your pocket doesn’t care whether the frame is titanium or aluminum when the chip is barely ticking over.

Then we lit the fuse. We launched 3DMark Wildlife Extreme Stress Test on both phones and let the benchmark run. At the three-minute mark, we grabbed our first set of thermal snapshots. The titanium iPhone 16 Pro immediately revealed its weakness: a bright, compact hot patch on the right side, near the volume keys. Our FLIR One unit has a margin of error of about ±3 °C, but even with that in mind, the hot spot crept up to around 41 °C – more than just gently warm. Meanwhile, much of the rest of the frame remained noticeably cooler, showing that the titanium wasn’t distributing that heat particularly well.

The aluminum iPhone 17 Pro told a different story. At the same three-minute mark, the thermal image looked more like a smooth gradient than a single orange flare. The hottest point hovered around 36 °C, only a bit above the idle reading and a few degrees cooler than the 16 Pro’s hot patch. Instead of one thermal “burning point,” the whole frame was participating, which is exactly what you want. It means the heat is being shared and moved away from the delicate internals, even if the phone, as a whole, starts to feel a bit warmer in your palm.

Fast forward to the ten-minute mark, and the differences became even clearer. On the iPhone 16 Pro, the titanium frame still showed that tight, intense hot area, now around 45 °C. That’s the kind of temperature where metal stops feeling merely warm and starts feeling slightly uncomfortable when your finger lingers on it. It’s not dangerous, but you naturally adjust your grip to avoid that spot. Inside the phone, that concentrated heat cluster is exactly where the chip and power delivery components are working hardest, and they are the ones being stressed.

The iPhone 17 Pro, by contrast, looked like it had turned its entire body into a radiator. The hottest area had climbed to around 42 °C – warmer than it was at the three-minute mark, but still lower than the 16 Pro’s peak. More importantly, the frame was glowing quite uniformly in the FLIR view, indicating that the aluminum chassis was helping the vapor chamber share the thermal load. From the user’s perspective, the phone feels warmly consistent rather than patchy. From the chip’s perspective, the stress is distributed instead of concentrated in a single critical zone.

Once we stopped the stress test, we wanted to see how quickly both phones cooled down. After five minutes in standby, with screens off and no intensive tasks running, the titanium iPhone 16 Pro surprised us. Its localized hot spot had faded, and the whole body had evened out around roughly 36 °C. The aluminum iPhone 17 Pro, now also resting, settled to roughly the same temperature. The FLIR images were remarkably similar: both phones were still a bit warmer than their original idle state, but neither held a clear advantage.

Checking again ten minutes after stopping the test told a similar story. Neither phone had fully returned to its original idle baseline, yet both were comfortably in the “slightly warm” territory. The key takeaway here is that standby cooling isn’t where aluminum flexes its muscles. Once the processor calms down and power draw drops, the phones behave much more alike. What aluminum really changes is what happens while you are actively pushing the phone – gaming, editing, recording, or multitasking – not what happens once you put it face down on the table and walk away.

So what does this mean in real-world use? If you’re the kind of person who uses an iPhone as a social media machine, messaging hub, and light camera, you probably won’t notice a night-and-day difference in materials. Both titanium and aluminum will feel fine during casual scrolling. But if you play heavier 3D games, log long camera sessions, or often export big projects from a video editor, the aluminum iPhone 17 Pro behaves more like a small, well-designed laptop heatsink than a phone shell. You’ll feel a warmer frame against your fingers, but the chip inside will be able to hold higher performance for longer before throttling.

Of course, the switch to aluminum isn’t all upside. Stainless steel frames on older Pro models resisted dents better than today’s aluminum rails, even if they smudged instantly. Titanium on the 15 Pro and 16 Pro, for all its thermal downsides, brought incredible stiffness and scratch resistance to the frame. With the 17 Pro, early units already show tiny nicks and chips along the edges after short drops or bumps – something you rarely saw on stainless steel. In other words, Apple has traded some visible durability for better thermals and a more controlled performance curve.

Looking back at the FLIR photos, the verdict is fairly clear. The combination of an aluminum frame and a proper vapor chamber doesn’t magically turn the iPhone 17 Pro into a gaming PC in your pocket, but it does address the central problem we saw with the A17 generation: localized heat build-up and aggressive throttling. Under sustained load, the aluminum iPhone spreads heat more intelligently across its body, resulting in lower peak hot-spot temperatures and more stable performance. Once the workload stops, both phones cool in similar fashion, but by then the job – keeping the chip healthy and fast during the stressful part – is already done.

Aluminum versus titanium, then, isn’t really about which material feels more “Pro” when you pull your phone out of the box. It’s about how the device handles heat when every core is firing and the GPU is drawing as much power as the battery will allow. In that demanding moment, the iPhone 17 Pro’s aluminum shell and vapor chamber combo simply does a better job of managing the heat that modern mobile chips inevitably generate. Your fingers may notice a slightly toastier frame, but your games, renders, and exports will quietly benefit from it.

2 comments

ngl I miss the feel of the steel frames, but if aluminum means less throttling I kinda get the move

So basically Apple made the whole phone a hand warmer but at least my games wont lag lol