In an ironic twist of technological ambition, Chinese engineers attempting to reverse-engineer ASML’s sophisticated DUV lithography machines ended up breaking them – and had to call the Dutch company for help.

According to reports circulating in international media, a group of Chinese technicians tried to take apart ASML’s deep ultraviolet (DUV) lithography equipment to better understand its inner workings. The goal was clear: gain insights that might help China overcome one of the most formidable barriers in semiconductor production – the lack of access to cutting-edge lithography tools. But instead of a breakthrough, they were left with a pile of disassembled components and a frantic call to ASML for assistance.

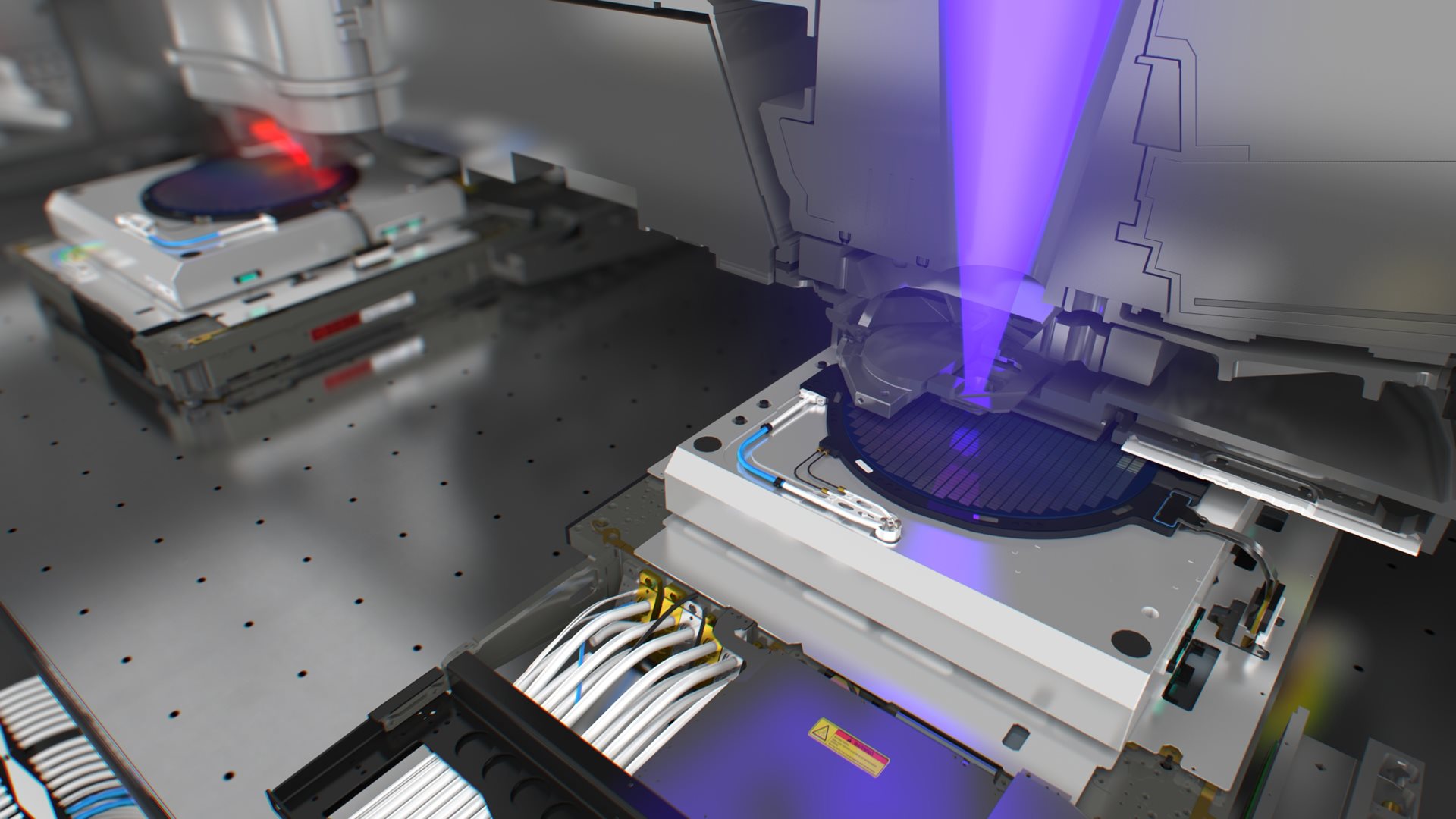

ASML, based in the Netherlands, is the undisputed leader in lithography technology – the process that etches the microscopic patterns forming the heart of every chip. Its extreme ultraviolet (EUV) systems remain under strict export controls, leaving Chinese manufacturers with only older DUV models. Even those, however, are incredibly complex, integrating precision optics, vacuum systems, and nanometer-level calibration routines that make them nearly impossible to replicate without the original blueprints and expertise.

When the Dutch engineers arrived in China, they quickly realized the machine hadn’t simply malfunctioned. It had been tampered with. Reports claim that it was obvious someone had attempted to take it apart and put it back together, resulting in severe mechanical and optical misalignments. In short, the machine was beyond local repair. While ASML has not officially confirmed this version of events, industry watchers note that the story aligns with China’s urgent drive for technological self-sufficiency.

For years, companies like SMIC have been constrained by their inability to access EUV tools, capping production at less advanced nodes. Reverse-engineering ASML’s DUV systems would, in theory, give China the leverage to produce more competitive chips. However, the task is monumental: each system involves tens of thousands of components, intricate calibration software, and proprietary materials that even a small misalignment could render useless.

Still, it’s not hard to understand China’s determination. The semiconductor supply chain is one of the few remaining levers of geopolitical control, with U.S. sanctions and export restrictions pressuring Chinese tech firms from multiple directions. Developing domestic lithography tools has become not just an economic goal, but a national mission.

Some observers see the failed disassembly not as a humiliation, but as an inevitable learning step. Trial and error has long driven innovation, and while this one may have ended with a broken DUV tool, it highlights China’s persistence in reducing dependence on Western technology. Others, however, see the event as a symbol of overreach – a reminder that copying complex machinery is not the same as mastering it.

As one industry expert put it, “You can’t just take apart an ASML machine and expect to understand it. It’s like disassembling a jet engine with a wrench set from a hardware store.”

Whether the story is exaggerated or entirely true, one thing is certain: the global chip race continues to be a high-stakes drama – where even a broken machine tells a story about ambition, limitation, and the relentless pursuit of technological independence.