All-in-one liquid coolers age – and not gracefully. As months roll into years, many AIOs lose their edge because tiny bits of manufacturing residue migrate through the loop and settle inside the CPU block’s microfins. Those fins are designed to maximize surface area; clog them with debris and you raise flow resistance, starve the hottest zones of coolant, and watch CPU temps creep upward.

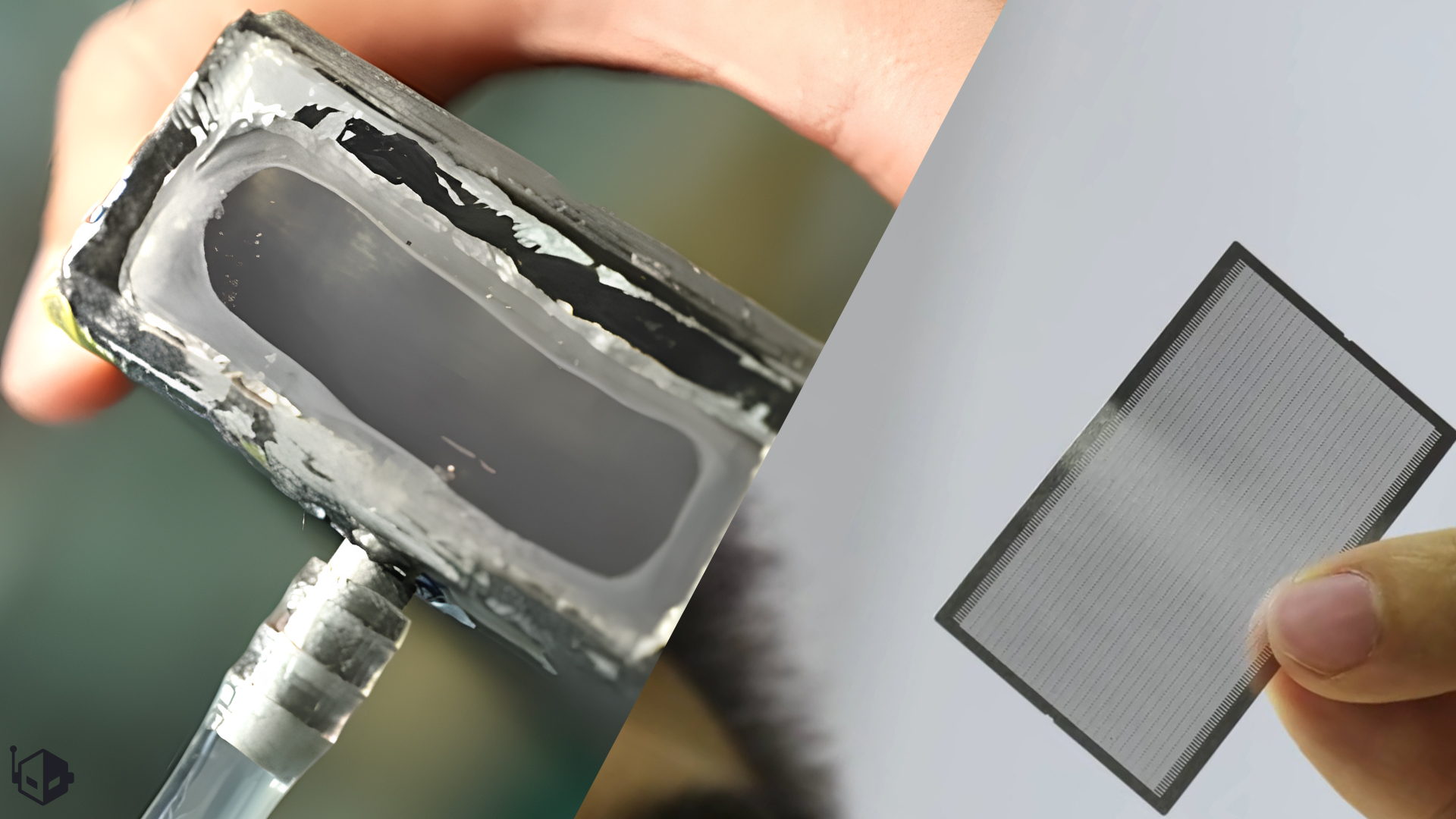

Cooler maker Valkyrie is tackling that predictable decline with a simple, engineering-first answer: a dedicated Flux Filter and cleaner radiator manufacturing for its new VK N360.

Why target flux? Radiators are brazed and soldered, and flux is the helper chemistry that protects joints from oxidation. Even after rinsing, trace residue can break loose later, especially under thermal cycling, and the circulating pump dutifully shuttles those particles straight toward the most delicate geometry in the system – the cold-plate microfins. Valkyrie places its Flux Filter at the radiator’s inlet, acting as a particulate trap before the loop’s narrowest pathways ever see the contaminants. It’s a low-cost part, but the positioning is critical: intercept debris upstream and you prevent the very failure mode that ages AIOs.

Hardware fixes seldom live alone. Valkyrie pairs the filter with what it calls low-flow radiator manufacturing intended to shed fewer particles from the start, then inspects each radiator internally before assembly to keep the loop as pristine as possible. On paper, that combination addresses both the origin and the path of contaminants: make less debris, and block what remains.

Does it work? Valkyrie’s own stress run on the VK N360 kept the coolant at 90°C+ for 72 hours – a punishing soak that accelerates aging – and the measured performance drift was reported as roughly +1°C. For context, many users see materially larger deltas over much longer real-world timelines, so a one-degree uptick after an accelerated torture test is a promising datapoint. Of course, third-party labs will need to replicate results with controlled test jigs and normalized fans, but the direction is encouraging.

There are practical implications for builders. A filter that captures flux before it reaches the cold plate can extend stable performance, delay the need for RMA or replacement, and preserve acoustic headroom because fans won’t need to spin as hard to chase lost efficiency. The obvious engineering trade-off – added restriction – should be small if the filter’s cross-section and mesh size are tuned to the pump curve. Custom loop veterans have long used in-line strainers for exactly this reason; bringing the idea to sealed AIOs feels overdue.

Equally noteworthy is the transparency. Many brands gloss over long-term degradation, yet Valkyrie is naming the enemy and showing its countermeasures. It won’t fix unrelated issues – silicon aging on hot CPUs is a different battlefield – but keeping the loop clean protects the cooler from harming itself. If wider testing confirms what Valkyrie is showing here, expect the flux-filter approach to become a checkbox feature across the AIO market, much like anti-vibration pads on fans or non-porous tubing blends did in earlier cycles.

Bottom line: the Valkyrie VK N360 marries a targeted Flux Filter with cleaner radiator processes to slow the march of performance decay. It’s a small part aimed at a big, boring problem – and that’s exactly how real reliability gains usually happen.

2 comments

as long as it keeps microfins clean, i’m in. cleaning a cold plate is zero fun lol

if corsair/nzxt copy this next year i won’t be shocked – it’s such an obvious fix